Posted by AllDayShirts on to Printing Techniques.

Starting a small business in the t-shirt industry is thrilling, but the vast array of decisions can seem daunting. Key among these decisions is the selection of the right print method, especially when balancing quality and price point. While traditional methods such as heat transfer or screen printing have their place, dye sublimation printers have emerged as a favorite. In the world of sublimation these printers not only offer the ability to print larger designs but also promise an impressive print resolution. If you're aiming to optimize quality without compromising on the price point, then dye sublimation printing should be at the top of your list. Dive in to discover the unmatched benefits of this advanced print method for budding entrepreneurs.

Sublimation printing is a way of transferring an image onto a given material permanently. The name comes from a scientific process where a substance changes from a solid into a gas without ever becoming a liquid.

In the case of sublimation printing, the printer ink is the substance that phases between a solid state and a gas state. Using a sublimation printer, you print your design onto specialty paper with the solid ink. Then, you use heat to apply the design onto the t-shirt you're making. The heat turns the ink into a gas, which binds to the fibers of the cloth. As it cools, it will phase back into a solid.

This process is permanent, which makes it great for clothing designs. Wearing, folding, and washing the t-shirt won't hurt the design at all. Unlike with heat transfer, the image won't flake, peel, or wrinkle.

To start printing t-shirts with this method, you will need some specialty equipment and instructions. Once you're set up, the process is an affordable way to print complex designs and images.

The basic steps are:

While the steps may be similar to heat transfer, the equipment and the quality are not the same. In heat transfer vs. photo sublimation, sublimation is going to get you a better final product.

Both methods involve printing your design and then transferring it to your product blank using heat. However, heat transfer merely attaches an image to the fabric, whereas sublimation makes the image part of the fabric.

Because sublimation printing works by triggering a chemical reaction, it only works on certain materials. Polyester is the best material for this method. Polyester blends also work well, but the fiber content should be at least 50% polyester for the best results. Our recommendation is the A4 Sublimation Performance Tee provides enhanced breathability, softness, and sweat protection at an unbeatable price.

There are processes to coat other materials with a chemical that will bond with the sublimation ink. While some people use this to print on cotton shirts, the color results are not as good and the printing quality suffers.

Sublimation printing also only works well on lighter-colored fabrics and materials. Remember, the ink is dyeing the fabric rather than sitting on top of it. A darker fabric will absorb the color, and you won't be able to see it. It's the same concept as trying to print a color photo onto black construction paper.

In addition to choosing the best t-shirts for sublimation that are compatible with the printing process, you'll also need a sublimation ink and sublimation paper as your main supplies.

Sublimation ink comes in cartridges just like regular inkjet ink. The inks are made up of dye particles that have been ground into a powder, suspended in a liquid or gel that won't dissolve them.

The ink goes through the sublimation process during printing and then again when you apply the design to your final product. During printing, the printer heats the ink to vaporize the particles in the liquid suspension. The gas dye particles then bond with the sublimation paper and phase back to a solid.

Once all of the colors in the image are on the sublimation paper, the printer will seal the ink onto the paper, keeping the image on the paper in solid form until the heat press stage.

You can use some regular inkjet printers with sublimation inks. However, once you've used an inkjet printer for sublimation printing, you can no longer use it with regular inkjet inks. Whatever printer you use for sublimation should only be used for sublimation.

Sublimation paper is a conduit for your design. It gives you the precision and color options of inkjet printing. Then it lets you transfer the resulting image onto surfaces that an inkjet printer couldn't print on, like fabric.

Sublimation paper is porous, meaning there is space in the fibers of the paper for the sublimation ink to soak in. It's also heat-resistant paper, which is necessary because of how hot the printer and the heat press machine have to be for sublimation to happen.

Depending on the size of the images you want to print, you can buy sublimation paper in sheets or rolls. Sheets come in the same sizes as standard copy paper: letter, legal, and 11" x 17". Rolls come in widths ranging from 24" to over 100".

You should also be mindful of the weight of your sublimation paper. Designs with more colors and more complex images will need heavier paper. When there is a lot of ink on the paper, it can weigh it down and cause it to curl up. If your paper curls, it will be harder to get your image on the t-shirt cleanly.

One of the greatest advantages of sublimation printing is the wide range of colors you can use. Sublimation printers use CMYO or CYMK colors (cyan, magenta, yellow, and orange for the former, and cyan, yellow, magenta, black for the latter) to print designs. These colors combine to make any hue you can imagine.

You don't print your design directly onto the fabric of the t-shirt. Instead, you print onto a coated paper made for sublimation printing. The paper will trap the solid ink in your design so that you can transfer the image onto your t-shirt.

Make sure to trim the edges of your design, leaving a thin margin of blank sublimation paper around the image. This removes any traces of excess ink from the transfer paper that could stain your shirt outside of the design.

You should also use a lint roller to pick up any debris or fibers from the surface of the shirt where you want your image. This will keep the design clean and make sure nothing but the sublimation ink is bonded to the shirt.

Once you've placed the image where you want it on the t-shirt, you'll need the heat press to trigger the sublimation process. Sublimation will only happen where there is ink, so you can use the paper's unprinted edges to secure your design to the t-shirt with a heat-safe adhesive. That way, the design doesn't shift during heating.

There is a range of heat press options depending on your budget and how much space you have. No matter which you get, it should be able to apply heat and pressure to an item.

A heat press has two flat plates that heat up to temperatures as high as 500°F (260°C). When you clamp an item with a sublimation design between them, the combined heat and pressure will cause the ink to phase from solid to gas, binding with the fabric.

You’ll want to make sure that you're only pressing the layer of the shirt that you want to dye. The sublimation ink will dye whatever parts of the fabric it comes into contact with and will easily bleed through multiple layers of fabric.

Depending on your heat-press machine, you may be able to slide your shirt over the bottom plate so that only the side you want to print on is touching the plate. Otherwise, slide parchment paper or a Teflon sheet between the layers of the shirt. Don't use wax paper, as the wax will melt onto your shirt and ruin your design.

We also recommend sliding parchment paper or Teflon sheets on the heat press’s plates before you use the machine. Excess ink can bleed onto the plates during the sublimation process. If you don’t get it off after one project, that ink might stain your next project

The temperatures for even a small heat press are incredibly high, so you should always use caution when operating one. You may want to use heat-resistant gloves or other protective gear.

The most important piece of equipment for your t-shirt sublimation business is, naturally, your sublimation printer. The entire process relies on this piece of equipment. Whether t-shirt printing is a hobby or a profession, you should invest in a high-quality printer that is affordable to maintain. After all, the best sublimation printers will yield the best results.

Here are our own recommendations for the top machines that anyone who takes sublimation seriously should consider.

The Epson EcoTank printers are known for their integrated ink tank system. But here we are specifically going to discuss the Epson Artisan 1430 may be an unusual recommendation as a sublimation printer because it wasn’t built for that purpose. This device is designed to transfer digital photographs into physical form and ink artwork onto blank discs. With that said, converting it into a machine capable of printing onto sublimation paper only requires a conversion kit and the right ink.

The rewards are more than worth the effort. All the advantages that Epson totes can apply just as well to the Artisan 1340’s sublimation printing as it does to its more typical uses. High-definition quality and colors, wireless connectivity with smartphone compatibility, and relatively swift printing are all great features for printing t-shirt designs. On top of that, it can handle prints as large as 13”x19”, which is excellent for all shirt sizes.

We should warn that Epson has discontinued the Artisan 1340. Still, it remains popular for a reason. If you can get your hands on one, you will receive a truly worthy printing machine. A new and unused Epson Artisan 1340 is available on Amazon for over $2400, and you may find lower-priced listings on other online marketplaces.

The Epson Workforce WF-7710 is another Epson inkjet printer that you can easily convert for sublimation work. It does not offer the same high-definition image quality as the Artisan 1340. With that said, its image quality is still excellent, and the model offers its own advantages. Like the Artisan, it can print large-scale jobs, up to 13"x19". Unlike the Artisan, Epson still manufactures it. You'll have an easier time finding it than the Artisan, and retailers are less likely to inflate the cost.

One significant benefit that the Epson Workforce WF-7710 boasts over the Artisan 1340 is its printing capacity. The latter could only hold 100 sheets, but the former can hold 250. The WF-7720, an alternative model, is even better. It is identical to the WF-7710 in many ways, including their printing speeds. However, the WF-7220 offers double the capacity with 500 sheets.

The Epson Workforce WF-7720 is the better choice for full-time t-shirt designers who want to print in bulk. Meanwhile, the Epson Workforce WF-7710 may be better for hobbyists and part-time printers. You can purchase either model for less than $700.

Unlike any of the three Epson printers discussed above, the Sawgrass SG400 and SG500 are built for sublimation printing. In fact, Sawgrass manufactures dedicated and purpose-built sublimation printers. This does more than save you money on conversion kits. It means all the features were implemented and fine-tuned for inking designs onto sublimation paper. People who personalize t-shirts for a living may find these printers an ideal match for their business.

The Sawgrass SG500 is built with efficiency in mind. This machine uses less power than other printers and minimizes ink consumption for a low cost per use. Just as important is that it can do all this without sacrificing high-definition image quality. It retails for about $600.

The Sawgrass SG400 has been discontinued as Sawgrass focuses on its successor, which offers backwards compatibility with SG400 accessories. Even so, it is highly reliable and has plenty of value. If you are on a budget and not a stickler for high resolution and wireless connectivity, the SG400 will serve you well. You can find used and refurbished machines of this make for a reduced price.

Like the Epson Artisan and Workforce printers described earlier, the DNP DS-RX1HS printer is advertised primarily for printing photographs. Like the Sawgrass SG400 and SG500, though, this machine was made for sublimation. Unlike any of those models, it retails at a relatively low $500. For that price, you receive a high-quality printer that’s built to last and capable of some surprising feats.

For starters, we’d recommend it for its large-capacity printing alone. It can hold up to 350 6”x8.” If you lower the size to 4”x6” prints, that capacity rockets up to 700. More impressive still is that the DNP DS-RX1HS prints faster than most other sublimation printers in its class. You can use it to pump out 290 4”x6” prints per hour, or one every 12.4 seconds. The speed does not diminish the excellent image quality at all.

The DNP DS-RX1HS comes with its disadvantages. The dimensions it can print don’t exceed 6”x8”, so you would have to stick to smaller designs and logos. There is no wireless connectivity, either. Still, this sublimation printer brings plenty of extraordinary benefits for a great price.

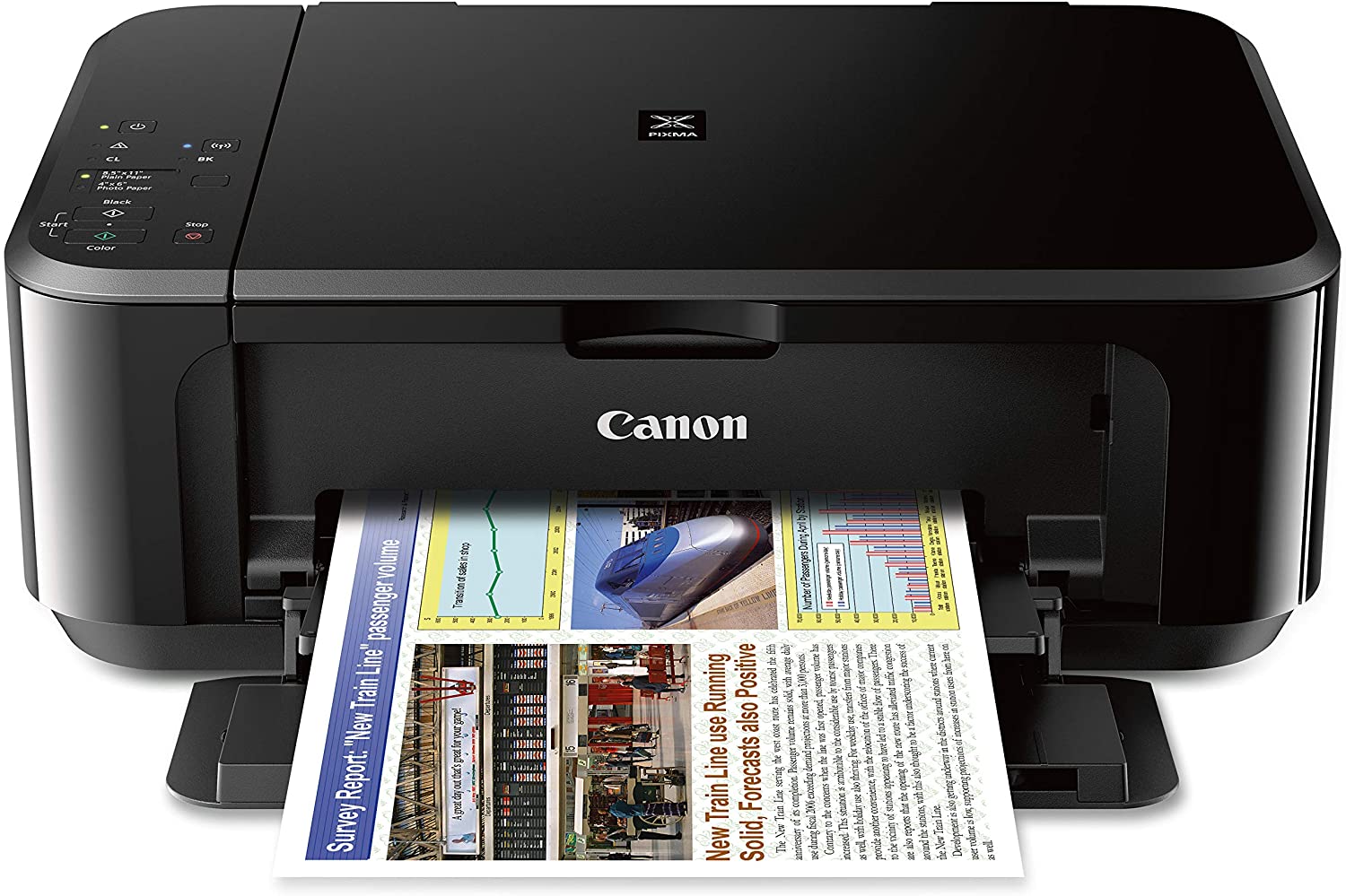

Canon is known primarily for cameras, but the company also brings the same emphasis on high-definition images to their lines of printers. Although these devices are marketed for their ability to print photographs, some are compatible with sublimation paper and ink. The Canon Pixma MG3620 is one such machine, and it is among the best from any manufacturer for personalizing T-shirts.

This printer is rather large, which lets it cover a great range of print sizes from 4”x6” to 8.5”x14”. It is not only wireless but compatible with Apple AirPrint and Google Cloud Print. If your designs are on your phone, you can connect to the Pixma and get printing. The print speed is remarkable: 5.7 images per minute for color designs, 9.9 per minute for black-and-white, all in excellent resolution and vibrant color. Perhaps the only real downside is the small carrying capacity: just 20 for 4”x6” paper.

In short, the Canon Pixma MG3620 deserves a spot among the best sublimation printers for t-shirts on the market. You can order one for just over $100 on Amazon. The Canon online store cuts the price nearly in half.

The t-shirt sublimation process might seem complicated on the surface, but it's an affordable way to make beautiful t-shirts for your business. Sublimation printers are a relatively small investment for a start-up business, and even the priciest models will pay for themselves in the long run. All you need is the right knowledge, a little practice, a little money, plenty of dedication, and especially an eye for quality.

The hunt for great quality does not just apply to sublimation printers. It applies to everything, including the garments that will serve as your canvas. AllDayShirts.com offers an astounding variety of blank t-shirts from the best brands at wholesale prices, and many are ripe for the sublimation treatment. With dozens of blank t-shirts for sublimation to choose from, your unique t-shirt printing business dream can quickly become a reality.